SINCE THE BEGINNING

Cranston Machinery has been family owned and its operations have been carried out in an open, honest, team oriented environment. The Companies longevity and strength as a manufacturer, supplier and employer is testament to the success and dedication of its people and business partners.

CRANSTON’S Mission and Philosophy

Be recognized and successful as a quality supplier of custom products, support and supplies. Through superior individual performance and team effectiveness, each employee will ensure this goal is achieved.

CRANSTON’S Achievements

Over the years, the CRANSTON family businesses have participated in several diverse industries creating an impressive history of Invention and Innovation. The following devices, machines, or systems are just a sampling of these many achievements – many are Industry firsts and involve US and/or international patents.

- Patents and Machinery for automatic wire strapping of wooden boxes, newspaper street bundles, and similar sized products

- Patent and Machinery for mechanical assembly of wooden boxes

- Patents and Machinery for automatic insertion of corrugated steel fasteners

- Patents and Machinery for automatically dispensing and folding wrappers on wood pulp bales

- Production system for Urethane molding.

- Patents and Machinery used for automatically wire strapping Military C-Rations, Lumber units, Wood pulp bales, Cotton bales, Synthetic fiber bales and Bales of Municipal waste and Recycled fibers (Twisted Knot Technologies)

- Complete production systems for automatically packaging wood pulp bales

- Automatic Machinery for retaining wood pulp bales with repulpable adhesive

- Complete production systems for feeding paper machine repulpers

- Patents and Wire Strapping Machinery using wire welding technologies

- Patents, International Specification, Machinery and Tools for Automatic Unitizing and Top Attachment lifting of wood pulp

- Complete production systems for automatically packaging paper rolls

- Patent and Machinery. Universal design, lifting beam. Automatic attach lift beam

- Patent and Machinery for water filled burning tables

- Production system for automatically sizing wooden doors

- Patent and handheld tools for cutting steel wire and flat banding

- Patents, Machinery and Hand tools for application and sealing of strapping made of paper

CRANSTON’S Trade Names, Acronyms, and Names associated with Cranston products.

- CWBM: Cranston Wire Binding Machines Company

- CMCO: Cranston Machinery Company

- Fuselok™: Trade name registered by Cranston for Cranston automatic wire strapping machines using welded joint technology.

- Twistlock™: Trade name registered by C. Tennant & Sons for marketing Cranston automatic wire strapping machines using twisted knot technology.

- Unitizer™: Cranston trade name for its automatic Unitizing machine.

- RapStrap™: Trade name registered by Cranston for marketing repulpable paper strap and Cranston’s automatic equipment to apply and seal it

- Handi-Bander™: Cranston trade name for its handheld RapStrap tension and seal tool

- RapPress™: Cranston trade name for its wrapper gluing machinery

- RapBond™: Cranston trade name for its repulpable wrapper adhesive

- Byrap™: Cranston trade name for its pre-cut sheet wrapper dispenser.

- Econorap™: Cranston trade name for its 1 piece wrapper dispenser.

- Byconorap™: Cranston trade name for its double action 1 piece wrapper dispenser.

- Enfold™: Cranston trade name for its current automatic wrapper folding machine

- Byfold™: Cranston trade name for its pre-1978 wrapper folding machine

- Wirelube™: Cranston trade name for its eco-friendly lubricants

- Excalibur™: Cranston trade name for its battery operated wire cutting system

- PWC™: Cranston trade name for its powered wire/steel band cutting system

- Crestlift™: Trade name registered by Cranston for Cranston automatic attaching lift frames.

- UNILIFT™: Cranston trade name for its manually operated lifting hook

- Uni-hook: Cranston trade name for its 2, 3 and 5mt pneumatic release lifting hooks

- Uni-latch: Cranston trade name for its 7.5mt pneumatic release lifting hook

- Web-latch: Cranston trade name for its 5 and 10mt pneumatic release lifting hook – webs

Established 1919

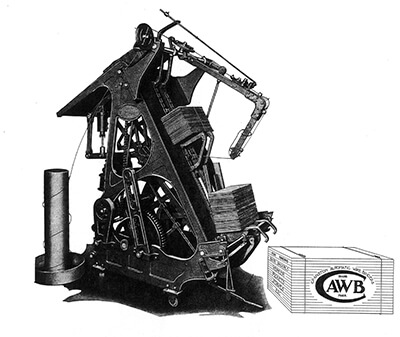

1919

Cranston Wire Binding Machines Co. (CWBM) applies for the first patents to protect industires’ new automative wire binding machinery. This equipment is used to bundle products, such as wooden shooks, newspapers, shingles, pickets, etc.

1928

Cranston Co incorporates in Spokane and Wenatchee Washington. Both were wooden box manufacturing companies utilizing patented assembly and wire strapping technologies by CWBM. Box distribution was direct to the West Coast produce growers.

1938

Cranston Machinery Co. Inc. incorporates in Oak Grove, Oregon. The company starts the business with multiple patents which ignite hi-volume manufacturing of machinery used for automatic insertion or corrugated steel fasteners, wooden box assembly machinery and new technologies for automatic wire strapping

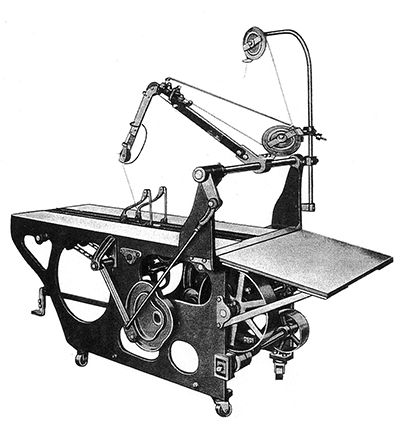

1947

Mutual Binding Machinery Co. (later to be known as Cranston Steel Strapping Company) designs and manufactures scores of automatic wire binding machinery for newspapers and other similar bundles. Distribution became global.

1953

Cranston revolutionizes pulp packing with the industry’s first automatic wire strapper. The following companies signed to provide global distribution: C Tennant & Sons of New York, Alhstrom Oy of Finland, and C.Itoch of Japan.

1965

Cranston extends its scope of supply and begins to produce complete packaging systems to pulp mills and package breakdown systems for the receiving paper mills. The company expands sales, manufacturing, and support in Canada for CMCO’s pulp and paper packaging products. Wire strapping company grows to include lumber and cotton, introducing the first wrapper gluing system to the pulp industry.

1970

Cranston participates in the development of what is now the international standard for Unitizing and Top Attachment Lifting for wood pulp which transformed the loading of pulp in open hatch vessels. Company reaches out in the paper mills and begins supply of paper roll handing and packaging equipment, resulting in pulp packaging system installation around the globe.

1980

Cranston opens is capabilites to the Pacific Northwest region and quickly builds a reputation and prominence as a quality designer and manufacturer of Custom Equipement and tools.

1990

Cranston Exands manufacturing to South Kora, delivering multiple roll handling and pulper feeding systems across the region. Also introducing FUSELOK wire welding technologies, to the synthetic fibers market in Europe and Asia in cooperation with AUTEFA of Germany.

2000

Crantson introduces its revolutionary RapStrap system to the pulp industry, utilizing strapping made from repulpable paper.

2010

Albert Cranston is awarded the prestigious “Erwin Adams, Lifetime Achievement award.” Company also expands deliveries into SE Asia and Europe, while boosting its focus on locak manufacturing and fabrication services for the PNW region.

2022

Today Cranston Machinery receives the Chamber of Commerce’s 2022 “Company of the Year” award.

2023

Although the first of the Cranston family companies was founded in 1919, Cranston Machinery formally celebrates its centennial.