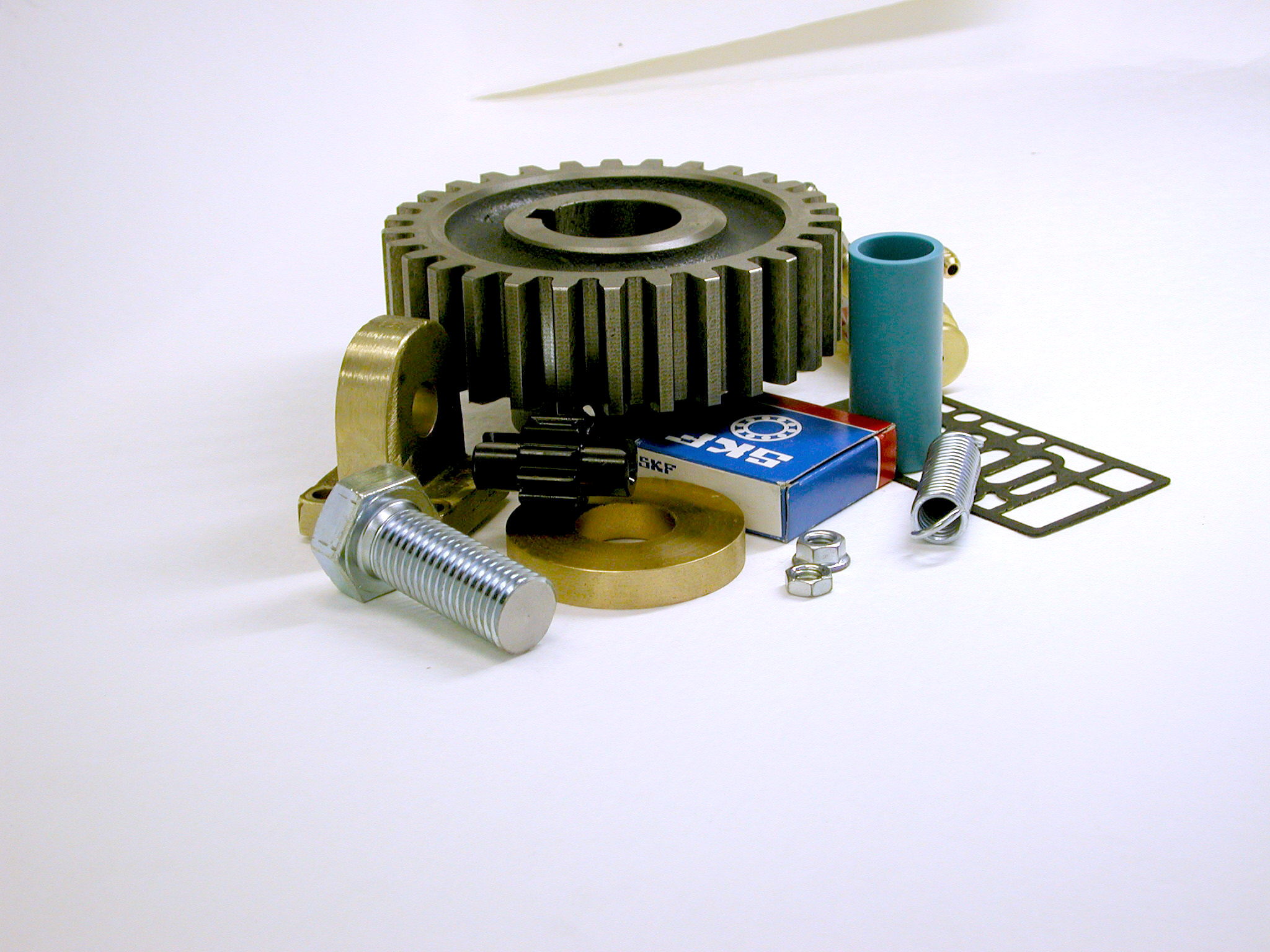

Parts

Cranston maintains a very generous inventory of wear parts for its tools and equipment. Typically, parts are shipped the same week and expediting is available for emergencies. When ordering parts, please consult your operator manual for correct Machine Serial, Parts Assembly and Part numbers. Replacement manuals, dating back to 1968, are available when needed.

Cranston ships parts internationally on a regular basis. Contact us for further information.

Contact Parts Department

TM

TM

Machinery Grade

Wire is a very successful strapping material where strength, safety, and economy are required. It can be manufactured in many sizes, strengths, and finishes. It is packaged in large quantities which promotes efficient handling, freight, storage, and long runs before reloading of machinery or systems.

High tensile galvanized steel wire is required in automatic wire strapping equipment. It is manufactured under rigid specifications on high-speed drawing and coiling equipment. The quality of the wire is critical to the proper operation of strapping equipment.

Cranston Machinery Co. is dedicated to producing high-speed, reliable machinery for those applications where automation is realistic and economically advantageous. New applications are analyzed for machine cost, with production rate, strap strength, and existing method of packaging as critical factors.

Cranston’s team can align you with a quality supplier and offers for this product when your needs call for it. Contact us for more information

Overhead Lifting

Cranston Specification #CS-001Wire Specification

Cranston Specification #CS-003

TM

TM

Paper Strapping

Eco Friendly – Operator Friendly – Repulpable Paper strapping made of multiple twisted paper cords (renewable and sustainable) assembled into a ribbon using a cold water repulpable adhesive which is compatible with most typical pulping processes.

RapStrap is manufactured in compliance with Cranston’s CS004 specifications as well as FDA 21CFR175.105 regulations and is bagged and sealed in Jumbo Coils containing 4876 Meters (16,000ft) of strapping. Coils are packed (9) coils to a pallet. Shipping materials are recyclable and include a heat-treated pallet per ISTP-15 specifications. The load arrangement has been tested and approved for Truck, Rail, Air and Ship transportation per ISTA-3E standards.

A standard 40′van or container will hold up to 135 coils, a 53′van will hold 180 coils.

An ultra Hi-density (18 coil) package is available for large shipments.

Cranston maintains a permanent stock of RapStrap.

Contact us for ordering this product

TM

TM

Wrapper Adhesive

Eco Friendly – Operator Friendly – Cold water repulpable adhesive is sprayed onto the bales wrapper and is compatible with most typical pulping processes.

RapBond is available in White or tinted in Blue or Green. RapBond is manufactured in compliance to Cranston’s CS008 specifications as well as FDA 21CFR175.105 regulations and is sealed and shipped in 205kg/450# fiber barrels (4 to a pallet). Larger totes can be quoted. Freezing must be avoided.

Working together, the RapPress machine system, RapBond adhesive and a well presented, quality wrapper create a surprisingly durable package for many types of sheeted dry pulp. The result is a well wrapped, easily re-pulped bale with a uniquely smooth clean appearance.

Using Cranston’s typical coverage estimate of approximately 11,000 bales per barrel, RapBond is the most cost-effective form of bale wrap and retention in use today.

Contact us for ordering this product

INKS FOR INK JET PRINTERS AND

UNITIZER SAFETY FACTOR PRINTERS

Ink for Cranston Ink Jet Printers (utilizing Matthews Printheads) are available in 19-liter/5-gallon or 1-liter containers in various colors.

Direct food contact ink, available only in Black, offers full compliance with the regulation FDA 21 CFR Parts 172, 182 or 184.

Ink for Cranston Drum, Stamp and Unitizing Safety Factor Printers. Available in 3.78 liter/1 gallon plastic containers. Six containers per case. Available Colors: Black, Red, Green.

Contact us for ordering this product