Pulp Packaging

With over 7 decades of experience and global installations processing market, fluff, dissolving, block, bagasse, and wet pulp, Cranston is uniquely equipped to help you develop a new system or upgrade an existing packaging system. Solutions for conveying, weighing, pressing, wrapping, printing, strapping/retention, stacking and unitizing are shown in the gallery.

Cranston finishing technologies include fixed or adjustable equipment, custom data systems, and the latest safety provisions. Cranston’s latest line of EP (Electric Pneumatic) equipment offers the highest levels of production and reliability while reducing noise, housekeeping, and maintenance costs. The latest 2D bar codes are available in Food Grade Ink and are scannable at extended distances.

Standard Products:

*Conveying (chain, belt, flat, incline, shuttle, swing, turns, elevator) *Handling Equipment *Weighing Stations *Bale Presses ( 150 – 2600 MT ) *Precut Sheet and Rolled Stock Wrapper Dispensers *Bale Retention – (3) choices: wire, paper strap and adhesive *Ink-Jet Printing:logos and barcodes *Wrapped Folding *Stacking *Unitizing *Safety Barriers *Automation

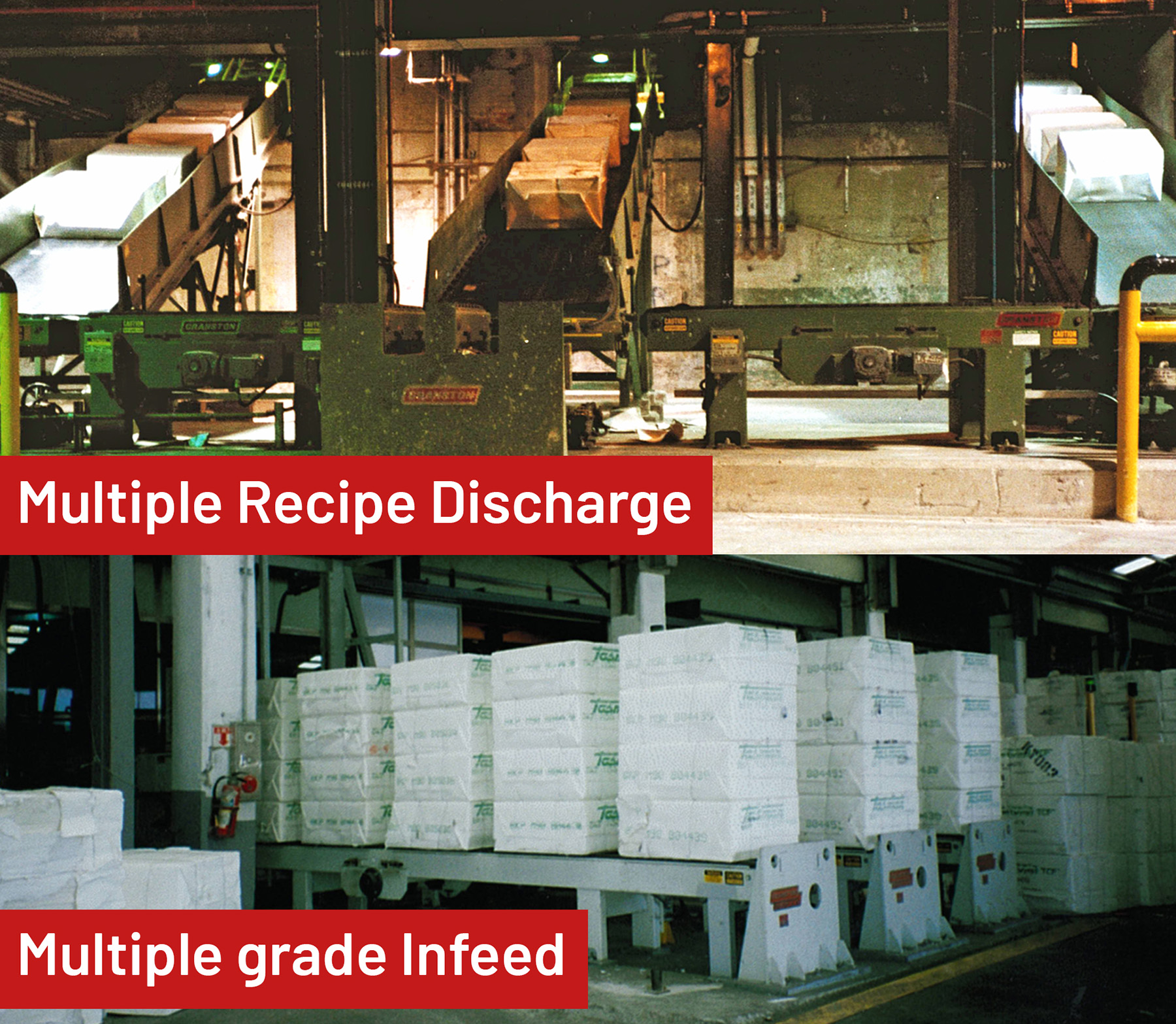

Pulper Feeding

Each solution for feeding baled, rolled or broke stock into a single or set of pulpers starts with a custom evaluation. Pulper capabilities, production requirements, package varieties, safety and area or building restrictions need to be balanced. Cranston’s proven solutions range from simple conveyors and manual dewiring stations to automated destacking and recipe make-up equipment for managing multiple grades and materials. Solutions for conveying, destacking, pallet removal, wire cutting, wire coiling, and batch make-up are shown in the gallery.

Standard Products:

*Conveying (chain, belt, flat, incline, shuttle, swing, turns, elevator) *unit/Stack Breakdown ( downending / destacking ) *Guillotine *Broke Carts *Dewiring Tools *Safety Barriers *Automation

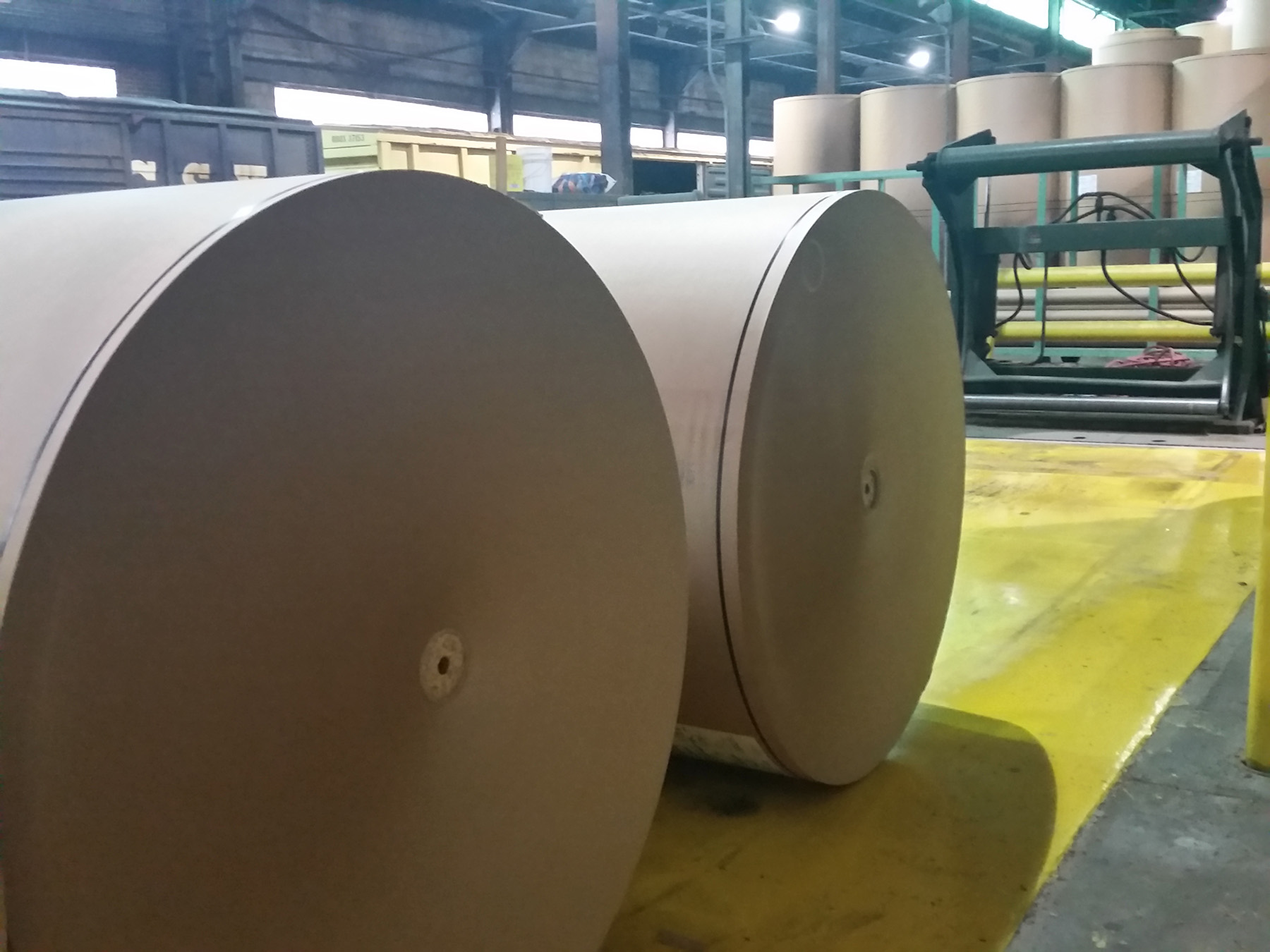

Roll Handling

Cranston Roll Handling Systems and equipment can be found at paper, pulp and board mills receiving sets of rolls at re-winders, transferring individual rolls between processes, providing basic packaging, or feeding sheeters and laminating systems at converting facilities. Durability is a keystone of Cranston designs.

Solutions for conveying, weighing, printing, kicking/stopping, lifting/lowering, strapping, upending are shown in the gallery.

Standard Products:

*Sorting Stops *Cushions *Kickers *Arm Elevators *Centering and Grouping Units *Turning Rolls *In Floor Carts *Upenders, Decks and Ramps *Safety Barriers and Automation *Conveying (chain, belt, flat, incline, shuttle, swing, turns, elevator)

Packaging, Pulper Feeding, Converting, and Rewinding

Cranston’s handling equipment connects the key components in your plant site and are proven for use with pulp bales (dry, wet, block), broke, rolls (paper, pulp, tissue, board) as well as recycled fiber bales. Cranston Handling and Manipulation equipment is standard in the EP (Electric and Pneumatic) format. Only limited pieces of equipment utilize Hydraulics. All are powered and controlled for smooth, quiet, dependable operation.

Typical products

chain, belt, slat and cart style conveyors are used to create product movement in straight, turn, swing, incline, shuttle, jump, hinge, and vertical travel configurations. A wide range of accessories such as tilt modules, span bridges, side pans, food grade surfaces, and central lube optimize the equipment to meet your project specifications.

centering units, servo-controlled lift and rotate modules, as well as a range of tipping and rolling devises.

sorting stops, cushions, kickers, arm elevators, centering and grouping units, turning rolls, in floor carts, upenders, decks, and ramps.

to suit new and retrofit applications.

Bale Finishing Packaging

With nearly 7 decades of experience and global installations processing market, fluff, dissolving, block, bagasse, and wet pulp, Cranston is uniquely equipped to help you develop a new system or upgrade an existing packaging system.

Cranston finishing technologies include fixed or computer-controlled adjustable packaging equipment, custom data systems, and the latest safety provisions. Cranston’s latest line of EP (Electric Pneumatic) equipment offers the highest levels of production and reliability while reducing noise, housekeeping, and maintenance costs. The latest 2D bar codes are available in Food Grade Ink and are scannable at extended distances.

Standard Products

- Handling equipment

- Weighing stations

- Bale presses (150 – 2600MT)

- Precut sheet and rolled stock wrapper dispensers

- Bale retention – (3) choices; wire, paper strap, and adhesive

- Ink-Jet Printing; logos and barcodes

- Wrapper folding

- Stacking

- Unitizing