LIFTING HOOKS

Cranston’s lifting hooks are designed specifically for top attachment lifting and are most commonly hung from multiple spreader bars or lifting frames. All Cranston hooks are manually attached to the lifting strap and then once in the unloading location, depending on the model, can either be removed or unlocked manually and or pneumatically from a remote location (typically with a manual striker plate or electric solenoid). All items in this product line are designed for outdoor maritime use. Acceptable applications can be multiple strands of wire, wire ropes, steel rings, fabric slings, or flat steel slings. All must be carefully reviewed and tested.

UNILIFT ™

Manually opened latch: 2 MT SWLCranston Specification #CS007 (User Guide for all models of UNILIFTS ™)

Hook Bulletins (bulletins are model specific and include replacement part diagrams and maintenance details)

Specifications Watch Video

WEBLATCH™

Pneumatic or Manually unlocked: 5MT SWL / 10MT SWLCranston Specification #CS006 (User Guide for all models of WEBLATCHS™)

Hook Bulletins (bulletins are model specific and include replacement part diagrams and maintenance details)

DownloadSpecifications Watch Video

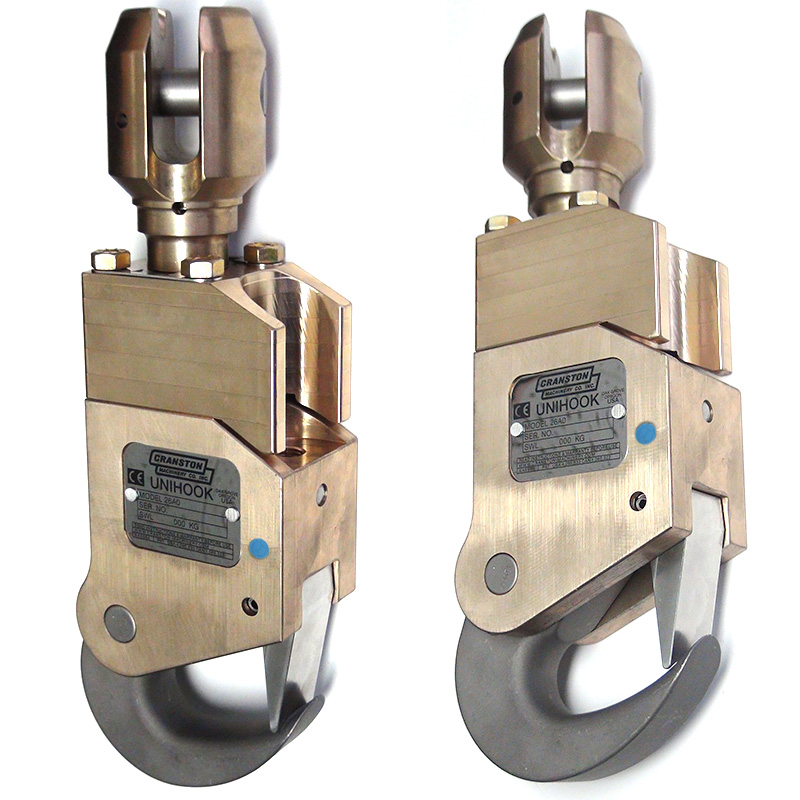

UNIHOOK™

Pneumatic unlock: 3MT SWL (Fixed Cap, 180° or 360° swivel)Cranston Specification #CS005 (User Guide for all models of UNIHOOKS™ including the new low pressure models)

Hook Bulletins (bulletins are model specific and include replacement part diagrams and maintenance details)

DownloadUNIHOOK™ Disassembly & Assembly Procesures – 446 Watch Video

Cranston has a calculator for estimating gas consumption per cycle for release kits and complete frame systems.

- a. Required data: number of hooks, type of hook, anticipated lengths of plumbing and selected release option (pneumatic or electric).

- I. Pneumatic timers are driven by gas and consume a significant amount of gas from the tanks per cycle. The more efficient electrical solenoid valves and electric timers require power from the crane or an integrated battery system. It is most common today for a release kit or frame to have a battery system, electric valve and timer plus striker plate activated pneumatic valve/timers as back-up in case the electrics are not available.

- b. The gas efficiency of the overall pneumatic system benefits by reducing operating pressures. See Cranston’s new low pressure hooks.

Once the required gas consumption and estimated lifts per day is estimated, Cranston’s team can assist with tank size and quantity selection.

- c. Tank handling, proximity to filling stations, and climate are normally considered when selecting a tank package.

- d. Smaller tanks such as 3.0ft3 (thermos size) to 80ft3 (standard scuba tank) / .085m3 to 2.26m3 operating at 3000psi / 206bar are lighter and easier to handle without equipment.

- e. When power is provided on the frame, an optional air compressor with accumulator tank is available.

- f. Larger industrial tanks, such as 200ft3 / 5.6m3 operating at 2200psi / 157bar are also common but require equipment for handling. Often multiple tanks are incorporated, one active and on-device standbys.

- g. Cranston provides tanks for Air, Breathable air, or Nitrogen gases. Compressed air is still common; however, filling stations for breathable air and nitrogen typically offer enhanced filtration which promotes reliability. Nitrogen is a dryer gas which further enhances reliability; it has become the standard gas for the larger tanks. Optional filters and Lubricators are available.

Pneumatic release Kits

If you already have a lifting frame and need an upgrade for pneumatic release hooks, consider a Cranston pneumatic release kit. Each kit includes the specified number of Cranston hooks with quick disconnect hose fittings, a spool of pneumatic hose, a custom bag of pneumatic fittings (connectors, T’s, etc.), pneumatic schematic, wiring schematic (if applicable), assembly instruction, and a fabricated steel support box. The support box is welded or bolted on your frame and includes Air or Nitrogen bottles, regulators, all internal plumbing, a pair of manual striker plate modules with pneumatic valves, optional compressors with electrical terminals box, optional remote control modules with solenoid valves, and battery.

Specifications

Watch Video

Lifting Frames

Cranston hooks and or lifting gear can be found in ports around the globe hard at work lifting slings made of multiple wires, flat steel banding, fabric webs, bags, wire ropes, and rings. These quality Cranston products are used to move Pulp, Paper, Lumber, Plywood, Metals, Fruits, Chemicals, and more.

Durability, Reliability, and Safety are the cornerstones of this product line.

The first lifting frames used for loading and unloading unitized wood pulp were manufactured by Cranston Machinery in the early 1970’s. These products and the system specification CS- 001 were created in cooperation with a major steamship line and leading pulp company. Since then, the capabilities and uses of these products whether dockside or in a warehouse have flourished.